Building Alabama

This article was originally published on Nov. 10, 2022 by Community College Daily and has been used with permission.

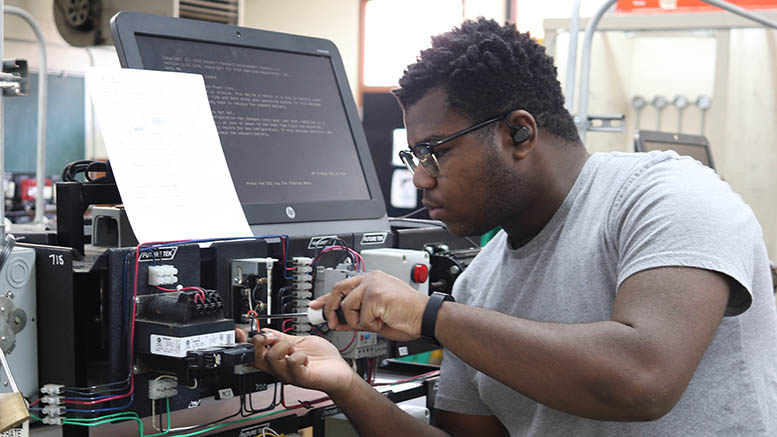

Wallace Community College-Selma Student Cameron Diaz trains in preparation for NCCER testing inside his college’s electrical lab. (Photo: Jeremiah Hunyh)

The need for workers in two of Alabama’s fastest-growing industries is being met with specialized, nationally recognized training at Alabama’s community colleges that prepare both students and the state for growth, even before the student obtains an associate degree.

Several community colleges in Alabama are steadily training residents across several construction and manufacturing trades through a partnership with the National Center for Construction Education and Research (NCCER). NCCER offers standardized training curricula, testing and credentialing in multiple disciplines – including carpentry, plumbing, pipefitting, electrical and welding – by combining both knowledge and performance components to give students and trainees well-rounded preparation to work in construction and manufacturing industry sectors.

More than 25,000 training modules have been completed by students across the Alabama Community College System in the last five years. Darrell Barlow, senior outreach coordinator for the Go Build Alabama campaign that educates young residents on the value of skilled trades careers, said there are 111 trades in the construction industry in Alabama.

The credentials have gained the attention of leading companies and organizations who work to strengthen the future of construction and manufacturing.

“The knowledge, skills and abilities confirm aptitude of program completers to prospective industrial employers,” said Kristie Kelley, executive director of the Central Gulf Industrial Alliance (CGIA) that focuses on improving safety, workforce development, quality and productivity of its member organizations.

She added: “CGIA’s members, which include industrial owners, contractors and associates, typically hire candidates with electrical, instrumentation, mechanical, pipefitting and welding skills and credentials. Although some positions require an associate or bachelor’s degree, most entry-level positions do not and the company will train the candidate once they are hired.”

Serving a need

The construction and manufacturing industries in Alabama represent a combined $41.5 billion according to the U.S. Bureau of Economic Analysis. Many students learning a craft through NCCER curricula will obtain credentials, which represent knowledge and skills obtained through training. These can be earned in addition to their associate degree in their craft.

NCCER’s curricula of more than 70 titles contain course maps with recommended hours for delivering content within each level. These recommendations meet or exceed the U.S. Department of Labor’s requirements for apprenticeship. Instructors may tailor their training programs in a way they feel will have the most impact on their students.

“The need for skilled craft professionals in fields like construction and manufacturing continues to grow. Both the current construction workforce and the infrastructure they serve are aging, and an overall lack of interest in these careers is among the contributing factors to a worsening skills gap,” said NCCER President and CEO Boyd Worsham.

“To meet the demand for current and future building and maintenance projects, it is imperative to both recruit talented individuals to pursue careers in the trades as well as provide high-quality technical training and skills development,” he said.

A closer look

How the credentials impact Alabama’s residents can be seen throughout the state. Although it operates in one of the state’s most rural and high-poverty regions, Wallace Community College Selma is helping students find pathways to successful and life-changing career opportunities.

“NCCER credentials allow students to see a way out from where they are,” said Wallace Selma electrical instructor Eric Rogers. “A lot of our younger kids are economically stressed, so for them to talk to their friends and see how their lives were changed for the better because of credentials that boosted their careers, it’s something they respect and look towards. These students are learning a skill that can help them grow a family.”

Rogers said a significant benefit of NCCER is that the credentials don’t expire. That fact, coupled with giving students new skills to build their futures, particularly helps young adults take the time they need to find their passion and direction in life.

“I wanted to pursue something other than the family nail salon,” said Jeremiah Huynh, an electrical student at Wallace Selma. “I heard about electrical and the good prospect for jobs. With the NCCER credentials it was a lot of information and a lot to learn about safety, and because of that my options are open with some great companies.”

Preparing for life after prison

Ingram State Technical College in Deatsville is unique in that all its students are incarcerated individuals. Through offering skilled trades training to adults in correctional facilities, Ingram helps prepare these individuals for a better future while reducing the rate of recidivism.

“Our goal at Ingram is to provide students with the skills needed to secure meaningful employment as they transition from incarceration, significantly enhancing their chances of success,” said Ingram President Annette Funderburk.

Among the 20 career fields that Ingram provides technical training for are several construction and manufacturing crafts using NCCER curricula. Students who progress through these programs earn industry-recognized credentials.

“For students who may not have experienced great success in the classroom previously, the credentials they earn through NCCER are tangible proof they can accomplish their goals,” said Ingram carpentry instructor Eddie Lucas.

Welding winners

Craft training helps prepare individuals for a successful career in the trades. But for a few students at Jefferson State Community College, it also prepared them to compete for championships.

Jefferson State welding students Payton Schmitt, Clayton Womack and Doug Diaz recently participated in Project MFG’s Clash of Trades. Schmitt won the competition and was crowned “Project MFG National Welding Champion” while Womack finished second.

After earning a four-year business degree but being unable to find a good career fit, Schmitt discovered a passion for welding when his dad bought a cheap welder for the garage. Now going through the NCCER welding program at Jefferson State, he has goals to open his own welding shop someday.

“With the money I won I will be able to do so much.” said Schmitt. “As far as starting my own business, I will be buying nothing but big tools with it.”

Jefferson State President Keith Brown said that the accolades are a good indicator of the welding program’s quality and direction.

“To win both first and second place in a national competition shows our welding program is hitting the mark and preparing students for rewarding careers,” Brown said.

Interested in receiving more great construction news, research and content from NCCER? Click here to join our mailing list!